The Ground wire is a wire directly connecTed to the earth. It can also be called a safety return line. In times of danger, it directly transfers high voltage to the earth, which is regarded as a lifeline. Due to poor insulation performance or humid environment of use of household electrical equipment, the outer shell of the equipment will have a certain amount of static electricity, and in severe cases, electric shock accidents may occur. In order to avoid accidents, you can connect a wire to the metal shell of the electrical appliance and connect the other end of the wire to the earth. Once the electrical appliance leaks, the ground wire will bring static electricity to the earth and release it. In electrical appliances, the grounding wire is a line connected to the shell and other parts of the electrical equipment to promptly conduct away unsafe charges or leakage currents generated due to various reasons.

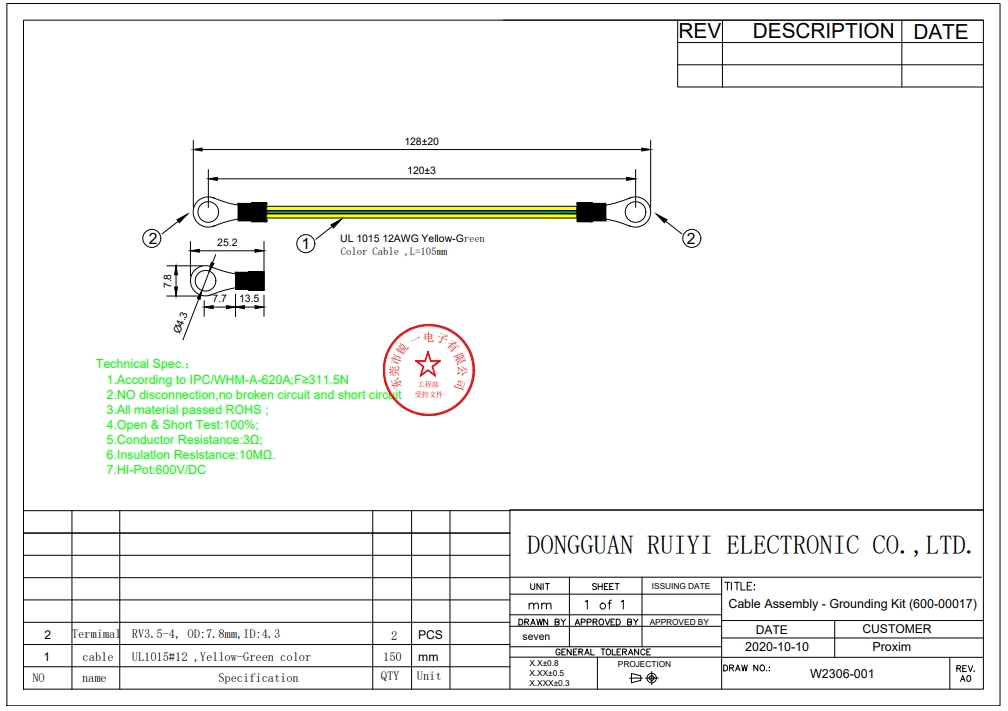

| Product Description | |

| Products | UL1015#12AWG.cable |

| Terminal | RV3.4-4 or OT 3.5-4 |

| Wire | tinned core, PVC jacket |

| Rated temperature | -25to +105℃ |

| Wire harness | PVC |

| Applicable current | 30A |

| Applicable voltage | 600V AC/DC |

| Flammability rating | 94V-0, VW-1, CSA |

Packaging & Shipp | |

Packaging | PE bag per pcs Customized packaging is available |

Carton size | 40cm*30cm*25 cm. Customized carton is available |

Shipping by air | 2-7days |

Shipping by vessel | 10-25days depend on the port of destination |

Logistics and transportation | sea transportation/air transportation/land transportation |

Payment method | TT |

Minimum order quantity | 200pcs |

Delivery time | 15~25D |

Supply capacity/month | 50000PCS |

In electrical systems, the ground wire serves several essential purposes:

Safety Grounding: The primary purpose of a ground wire is to provide a safe path for electric current to flow into the ground in the event of a device malfunction, preventing the current from passing through a person or other equipment and causing electric shocks. This is crucial for ensuring the safety of people and animals.

Safety Grounding: The primary purpose of a ground wire is to provide a safe path for electric current to flow into the ground in the event of a device malfunction, preventing the current from passing through a person or other equipment and causing electric shocks. This is crucial for ensuring the safety of people and animals.

Equipment Protection: Ground wires help dissipate static charges and electromagnetic interference, reducing the risk of equipment damage and enhancing the reliability and lifespan of devices.

Protecting Electrical Systems: In cases of lightning strikes, power surges, or other electrical disturbances, the ground wire can channel excessive charges into the ground, safeguarding the entire electrical system from damage.

Ensuring System Stability: Ground wires contribute to maintaining the stability of electrical systems by reducing electrical interference and electromagnetic disturbances, improving the performance and reliability of the system.

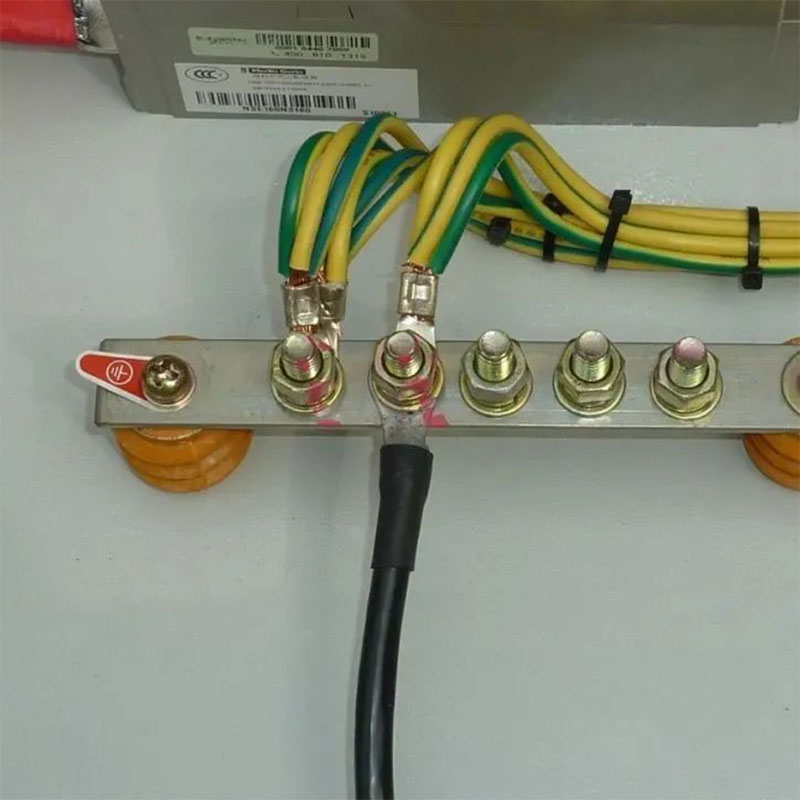

In many countries and regions, proper grounding is mandatory according to electrical safety standards to ensure the safe operation of buildings, homes, and industrial equipment. The ground wire is typically connected to the grounding electrode of a building or an underground grounding system, establishing a secure electrical connection with the ground and creating a safe electrical environment.

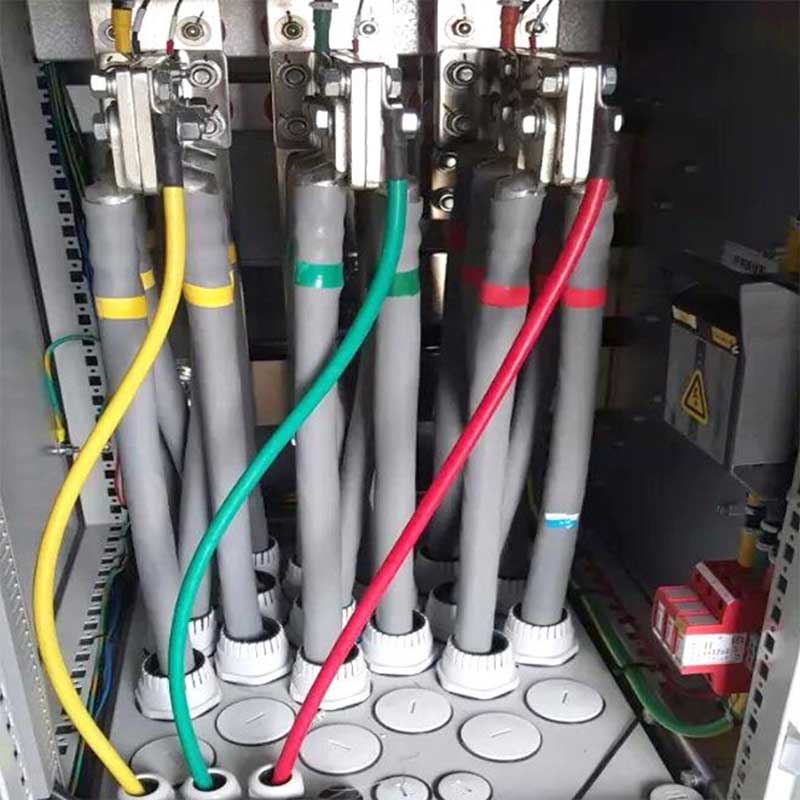

The ground wire finds widespread applications in diverse fields, including household appliances, medical devices, machinery, power facilities, automation equipment, and 5G networks.

The ground wire finds widespread applications in diverse fields, including household appliances, medical devices, machinery, power facilities, automation equipment, and 5G networks.

In household appliances, it ensures the safety of devices like refrigerators and microwaves.

In medical equipment, the ground wire is vital for patient safety, preventing electric shocks.

In machinery, it dissipates static electricity, reducing the risk of damage and enhancing reliability. Power facilities rely on ground wires for grounding transformers and other equipment, ensuring operational safety.

In automation equipment, it safeguards electronic components from electrostatic discharge.

In the context of 5G networks, ground wires are crucial for grounding cell towers and other network infrastructure, ensuring stable and secure communication.

Overall, the ground wire's applications are diverse, ensuring safety, reliability, and proper functioning across various sectors.

Merchant FAQ

What’s the Payment Term?

Normally, TT 50% before prototype sample preparing or part design, 100% in advanced before delivery. If payment is over $5000 or the big order placed, the payment term could be discussed.

How About the Delivery?

Normally we arrange air express like DHL, UPS, or FedEx etc. for samples, ocean shipping for heavy production. Besides, customers specify also is acceptable.

When Will You Start to Help Design?

We sketch simple solution for initial discussion, after quotation and order start to drawing then double confirm with client

Product Q&A

The ground wire in industrial machinery safeguards both equipment and personnel. By grounding metal parts, it prevents static electricity buildup, reducing the risk of sparks in potentially explosive environments. Grounding also ensures the machinery operates without electromagnetic interference, maintaining precision and reliability.

Grounding in power facilities, including substations, is essential for fault protection and ensuring the safety of workers. Ground wires are used to ground transformers and other equipment, diverting fault currents safely into the ground. Proper grounding prevents damage to equipment and minimizes downtime.

In automation equipment, sensitive electronic components are protected from electrostatic discharge (ESD) through the ground wire. ESD can cause irreparable damage to microchips and other electronic parts. Grounding provides a pathway for static electricity to discharge harmlessly, preserving the equipment's functionality.

In commercial buildings, the ground wire contributes significantly to electrical safety. By grounding metal structures, outlets, and appliances, it prevents electric shocks and reduces fire hazards. Proper grounding is a fundamental aspect of building codes and regulations, ensuring the safety of occupants and equipment.

There are several types of grounding systems, including single-point grounding and multiple-point grounding. Single-point grounding connects all equipment to a single grounding point, while multiple-point grounding connects various equipment to different grounding points. The choice depends on the specific installation requirements and safety considerations.

In outdoor electrical installations, grounding is achieved by burying ground rods or plates in the earth and connecting them to the equipment. This ensures a low-resistance path for fault currents. Outdoor grounding is vital for electrical equipment exposed to environmental elements, protecting against damage and ensuring reliable operation.

When installing ground wires in residential areas, it's essential to follow local electrical codes and regulations. Ground wires should be properly connected, and their integrity should be regularly inspected. Homeowners should avoid tampering with ground wires to maintain their effectiveness and ensure electrical safety.

Grounding contributes significantly to fire prevention in industrial settings. By ensuring that equipment and metal structures are properly grounded, the risk of electrical fires caused by faulty wiring or equipment malfunctions is minimized. Grounding prevents the buildup of excess electrical energy, reducing the potential for sparks and fire hazards

If you also need the following products, you can also contact us:

Wire Cutting & Stripping

Wire Termination

Wire Soldering & Splicing

Custom Injection Molding

Sample Prototyping

Wire Harness Design & Production

Customized Retail Packaging

Custom Fabrication

OEM/ODM

our Advantages:

1.Connectors could be TE, Molex, JST, Deutsch, Hirschmann, Delphi, FCI,KET,JAE or equivalents.

2 .Cables can use UL.CCC,CE.VDE,CSA,AVS,AVSS,GXL,TXL,SXL,TWP,AEX,FLRY-A,FLRY-B...

3. Free Samples can be supplied after quotation confirmed.

4. Strict quality control following ISO9001:2015 , IATF16949-2016 management system.

5. All the products are 100% test before delivery

6. All kinds of our products are ROHS compliant.

7. ODM/OEM order, trial order and customized cable are welcomed.

8. Our engineers have more than 15years experience on wiring harness design so that we can work with you to find the best solution to not only meet requirements but also control costs.